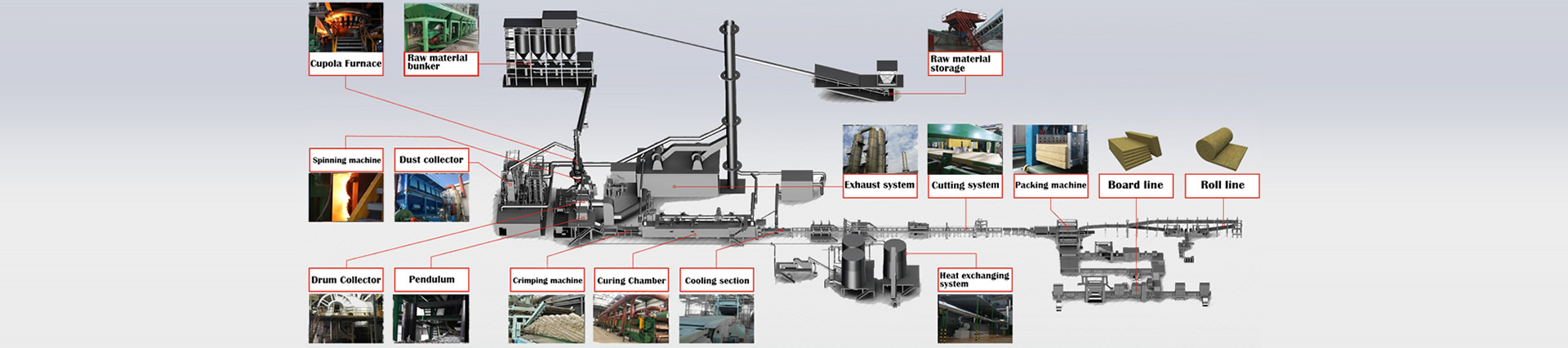

Mineral/stone/rock wool production lines: machinery for insulation

• Mixing, storage and weighing of raw materials for rock wool production lines

• Melting furnace for rock wool production lines

• Fiberizer, spinning machine for rock wool production lines

• Forming chamber for rock wool production lines

• Crimping machine, fiber orientation unit for rock wool

• Curing oven for rock wool production lines

• Cutting units for rock wool production lines

• Heated roller for rock wool production lines

• Roll up machine for rock wool production lines

• Packaging unit for rock wool production lines

• Mixing, storage and weighing of raw materials for rock wool production lines

.jpg)

The storage, mixing and weighing system for raw materials is located at the beginning of the rock wool production lines. From the melting of the mix of raw materials (mainly basalt stones and dolomite), are derived the stone wool fibers with suitable fiberizing systems. It is possible to add to the mixture several types of slag (such as blast furnace, copper), various additives to obtain a “biological” fiber and duly treated production waste.

The storage, mixing and weighing system for raw materials consists of:

• a series of hoppers for storage and accumulation of the raw material (various types of basalt stone, dolomite, slag, briquettes, coke)

• Weighing, extraction and mixing systems,

• Feeding system that transports the mixture to the melting furnace.

• Melting Furnace For Rock Wool Production Lines

.jpg)

The cupola furnace uses the combustion of the coke and the hot air to melt the mixture of raw materials transforming it into the melt. The melted rock is transformed into rock wool fibers. This type of melting furnace has the body that mainly consists of special steel resistant to high temperatures ( “steel for boiler”), the melting occurs at high temperature and the body of the furnace is water cooled. The circulation of the coolant liquid occurs with natural circulation system, without the aid of pumps, which makes the system inherently safe even in case of black-out. No need for emergency power generation systems. Some parts are coated in special refractory material (siphon, liquid output etc.). The main advantages of the cupola furnace are:

• Possibility of switch off / on in a short time;

• Reduced costs and easy maintenance;

• Ability to recycle waste of the production line turning it into briquettes;

• High operating flexibility.

The cupola furnace of HAIRUI is designed for capacity from 1.5-2 t/h to 5 t/h (of finished product).

• Fiberizer, spinning machine for rock wool production lines

.jpg)

The fiberizer or spinning machine is the technological heart of the system, which transforms the melt into fibers. According to the needs of the customers and capacity of product, HAIRUI can offer alternatives spinning machine.

• Forming chamber for rock wool production lines

The forming chamber is the part of the plant downstream from the spinning machine where the fiber is collected to form the material that is called “primary felt”: the fibers are blown away from the spinning machine and separated from the heavy parts (shots), are sprayed with a binder (phenolic, acrylic or ecological resin), then deposited through vacuum action on a special conveyor.

The shape and the aerodynamic study of this part of the plant is very important (with spinning machine) to ensure the high efficiency of the process and the uniform distribution of the fiber in the primary felt that assures the high quality of the final product. In fact there are different layers of primary felt (distributed on the main line by the pendulum) that compose the final product depending on the required density.

• Crimping machine, fiber orientation unit for rock wool

The crimping machine is the special unit for fiber orientation, installed before the curing oven. By acting on the orientation of the fibers the crimping improves the mechanical characteristics of the final product.

The vertical fiber orientation causes the high mechanical compressive strength and delamination strength. The tensile strength in the direction of the thickness increases from 5 to 10 times, this is a very important feature for the boards used outside of buildings/constructions.

• Curing oven for rock wool production lines

The curing oven is used for the polymerization of the binder contained in the felt, by hot air, in order to give to the final product its density and shape. HAIRUI has developed a new curing oven, completely redesigned to improve the maintenance and increase the efficiency of the machine (reducing the consumption of energy).

• Cutting units for rock wool production lines

.jpg)

The cutting units are used to complete the production process, cutting product to the requested size.

The cutting units generally include the following units:

• Cutting and trimming of the lateral edges

• Longitudinal slitting unit

• Thickness band saw

• Cross-cutting unit

Edges trimming unit

The edges trimming unit is used to cut the rock wool panels, after the curing oven and cooling, on both sides to reach the final width and have a smooth side surface. The machine is designed to mill the scraps after cutting: the ground product is sent to the forming chamber to be mixed with new fiber. The material does not pass through the fans, by this they have a high durability. It is also possible to use for transport suitably designed conveyor belts.

Longitudinal Cutter unit

The longitudinal slitting unit is used for material slitting in order to have final product with required dimension.

Thickness band saw

The thickness band saw is used to produce two or more layers of panels from one single felt, cutting it on the thickness. The advantage of this procedure is the reduction of the operating speed of the line and the obtaining of lower thickness and density.

Cross-cutting (Guillotine Shear Cutter )

The cross-cutting unit is used to cut the product at the required length. The panels of any density are usually cut with a rotating blade saw with one or two cutting heads, getting a clean cut, without dust or irregularity.

• Heated roller for rock wool production lines

Heated roller for rock wool production lines (On line facing unit for insulation materials) The heated roller is the unit used to couple the rock wool products with different facing materials (such as kraft paper, aluminum and glass veil) that are used as barrier for vapor and dust. Depending on the used facing materials (with or without pre-coupled plastic film), the bonding takes place with electrically heated roller which melts the plastic film, or it can happen at lower temperatures but with the addition of acrylic adhesives or a glue on water base. The facing can be done only on the bottom side of the product or on both sides.

• Roll up machine for rock wool production lines

Rolls up automatically the mattresses or felt.

The operator can choose the compression ratio suitable for the production type, so the software ensures the perfect uniformity, compression and circularity of the roll. The “wrapping” machine wraps automatically the roll from the outside with a plastic film or paper.

A special thermo-shrinking system seals the roll closing it at the ends. Depending on the type of plastic film, the cover can be partial or total.

• Packaging unit for rock wool production lines

.jpg)

The packaging unit is the final part of mineral wool production line.

The production process finishes with the packaging of the material.

HAIRUI proposes different packaging systems to meet the needs expressed by the customers. At the stacker discharge the packs are automatically wrapped in polythene and thermoshrinked.

During the packaging the packs, depending on the density, can be compressed, reducing its volume, so reducing the transportation costs.